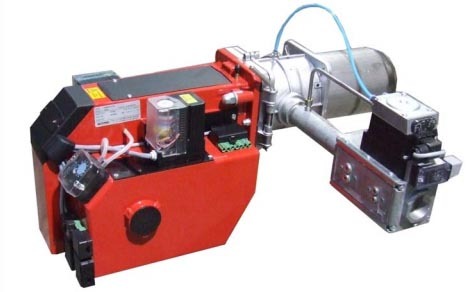

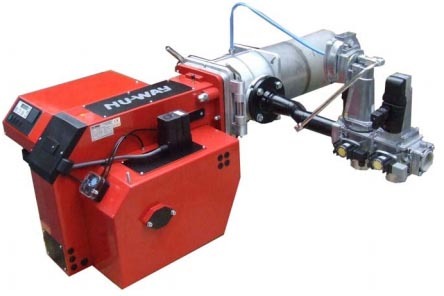

Single Stage Gas Burner

Single Stage Gas Burner Specification

- Condition

- New

- Size

- Sizes Available

- Usage

- Industrial

- Product Type

- Single Stage Gas Burner

- Color

- Red & Black

- Material

- Mild Steel

Single Stage Gas Burner Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 4 Week

About Single Stage Gas Burner

MG20/2-ZM-L-LN

Capacity - 225 to 1350 kW

These burners are available for use on natural gas, LPG, towns gas and biogas with-

- single stage on/off

- two stage high/low

- or modulating operation.

They are typically suited for commercial hot water boiler systems and steam boiler systems.

Installation of a gas-fired heating system must be performed in accordance with the applicable regulations

and guidelines. It is, therefore, the duty of the installation engineer to ensure that all regulations have been

read carefully and understood. Installation, start-up and maintenance must be performed with utmost care.

The burner must not be operated in rooms with high levels of air humidity (laundry rooms), dust or corrosive

vapours. The boiler room must be ventilated accordingly with ventilation air.

Giersch MG 20-LN Series gas burners are suitable for combustion of natural gas or liquid gas in accordance

with DIN EN 437 and are in compliance with the DIN EN 676 European standard.

Key Features:

- Quick and easy installation

- Reliable and trouble free operation

- Industry standard components available

- Most components can be easily accessed allowing for easy maintenance.

Also available:

- Larger gas train options

- Speed control (available only on certain models) to improve fuel efficiency and energy saving.

AllM series burners have been design in accordance with EN676 and EN267.

Robust Design for Industrial Applications

This Single Stage Gas Burner is expertly manufactured using mild steel, ensuring durability and resistance to industrial wear and tear. Its sturdy construction and vivid red and black color scheme make it not only functional but visually distinctive, catering to a wide array of industrial processes.

Versatile Sizing and Reliable Service

We understand the unique demands of different operations, which is why we offer the burner in multiple sizes. Our team provides comprehensive support, from distribution and export to maintenance and after-sales service, ensuring seamless integration into your industrial workflow.

FAQs of Single Stage Gas Burner:

Q: How should the Single Stage Gas Burner be installed for industrial use?

A: Installation should be performed by a qualified technician, ensuring that the burner is securely mounted and aligned with compatible gas lines and control systems. Our experienced service team in India can assist with setup and commissioning to guarantee safe and efficient operation.Q: What materials are used in manufacturing the gas burner?

A: The burner is constructed from mild steel, which delivers enhanced strength, durability, and resistance to high temperatures, making it ideal for continuous industrial operations.Q: When is periodic maintenance required for optimal performance?

A: Regular maintenance is recommended every 6 to 12 months, depending on usage intensity. Scheduled servicing helps maximize lifespan and maintain peak efficiency of the burner.Q: Where can I purchase or service the Single Stage Gas Burner in India?

A: You can obtain, service, or get support for this burner through our extensive distributor, exporter, importer, supplier, and trader network spread across India. Contact us directly for the nearest point of sale or service center.Q: What is the process for exporting this industrial burner overseas?

A: As a recognized exporter, we handle all necessary documentation, quality checks, and logistics to facilitate smooth exportation. Get in touch for guidance through every step of the export process.Q: How is this gas burner generally used in industrial settings?

A: The burner is typically employed for heating, combustion, and energy generation in manufacturing plants, processing industries, and other intense operational environments, where dependable gas combustion is essential.Q: What are the primary benefits of choosing this Single Stage Gas Burner?

A: Key advantages include robust construction, efficient fuel usage, diverse sizing options, superior longevity, and local after-sales support. These features collectively ensure cost-effective and reliable combustion solutions for industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Nuway Gas Burners Category

Gas Furnace Burner

Minimum Order Quantity : 1 Unit

Product Type : Gas Furnace Burner

Condition : New

Usage : Industrial, Others

Color : Black

Size : Standard

Gas Fired Burner

Minimum Order Quantity : 1 Unit

Product Type : Gas Fired Burner

Condition : New

Usage : Industrial

Size : Standard

Gas Fired Infrared Burners

Minimum Order Quantity : 1 Unit

Product Type : Gas Fired Infrared Burners

Condition : New

Usage : Industrial

Color : Red & Black

Size : Sizes Available

High Temperature Gas Burner

Minimum Order Quantity : 1 Unit

Product Type : High Temperature Gas Burner

Condition : New

Usage : Industrial

Color : Red & Black

Size : Sizes Available

Send Inquiry

Send Inquiry