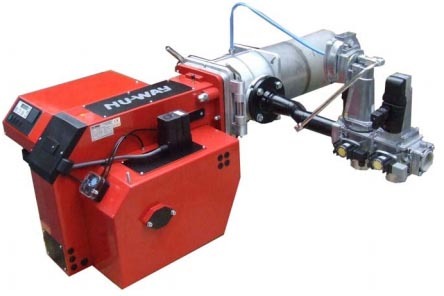

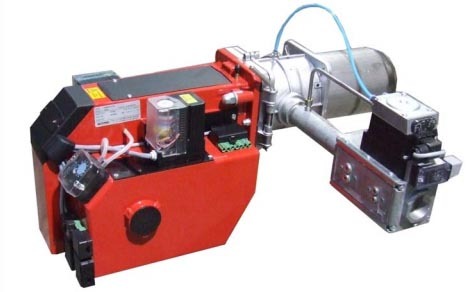

Modulating Gas Burner

Modulating Gas Burner Specification

- Condition

- New

- Usage

- Industrial

- Product Type

- Modulating Gas Burner

- Color

- Red & Black

- Material

- Stainless Steel

Modulating Gas Burner Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 4 Week

About Modulating Gas Burner

MG20/1-ZM-L-LN

Capacity - 225 to 860 kW

These burners are available for use on natural gas, LPG, towns gas and biogas with-

- single stage on/off

- two stage high/low

- or modulating operation.

They are typically suited for commercial hot water boiler systems and steam boiler systems.

Installation of a gas-fired heating system must be performed in accordance with the applicable regulations

and guidelines. It is, therefore, the duty of the installation engineer to ensure that all regulations have been

read carefully and understood. Installation, start-up and maintenance must be performed with utmost care.

The burner must not be operated in rooms with high levels of air humidity (laundry rooms), dust or corrosive

vapours. The boiler room must be ventilated accordingly with ventilation air.

Giersch MG 20-LN Series gas burners are suitable for combustion of natural gas or liquid gas in accordance

with DIN EN 437 and are in compliance with the DIN EN 676 European standard.

Key Features:

- Quick and easy installation

- Reliable and trouble free operation

- Industry standard components available

- Most components can be easily accessed allowing for easy maintenance.

Also available:

- Larger gas train options

- Speed control (available only on certain models) to improve fuel efficiency and energy saving.

AllM series burners have been design in accordance with EN676 and EN267.

Superior Performance and Efficiency

Our Modulating Gas Burner is engineered to provide reliable and efficient heating solutions for industrial settings. With its stainless steel construction, it withstands high temperatures and delivers uniform performance. The modulating capability enables precise flame adjustment, optimizing fuel use and minimizing emissions. This makes the burner a cost-effective and environmentally conscious choice for factories and processing plants.

Versatile Applications Across Industries

Designed for flexibility, the burner is suitable for a variety of industrial processes, including manufacturing, chemical processing, and metal works. Its robust build and adaptable design cater to the different requirements found in these environments. Whether you are upgrading existing systems or introducing new operations, our gas burner ensures dependable operation in challenging conditions.

FAQs of Modulating Gas Burner:

Q: How is a modulating gas burner different from a conventional gas burner?

A: A modulating gas burner adjusts its flame intensity automatically or via control systems to match the exact heating requirements. Unlike conventional burners that typically operate at fixed settings, this burners modulating feature enhances energy efficiency and ensures consistent combustion, which is especially beneficial in dynamic industrial environments.Q: What industrial processes can benefit from using this stainless steel gas burner?

A: This burner is suitable for a wide variety of industrial operations, such as boilers, furnaces, ovens, and dryers in manufacturing, chemical, and food processing industries. Its precise control and robust construction make it adaptable for diverse heating applications.Q: When should I consider replacing my existing industrial burner with this model?

A: You should consider upgrading if your current burner is experiencing frequent breakdowns, high fuel consumption, poor temperature control, or difficulty meeting emission standards. This new modulating gas burner offers improved reliability, efficiency, and compliance with modern industrial requirements.Q: Where can I source the Modulating Gas Burner in India?

A: We distribute, export, import, and supply the Modulating Gas Burner across India. Our extensive network ensures timely delivery and support for industrial clients nationwide, regardless of their location.Q: What is the process for installing or servicing the burner?

A: Installation and servicing are typically handled by certified technicians. Once delivered new, the burner is set up according to the manufacturers guidelines, including integration with control systems. Regular maintenance involves inspection, cleaning, and calibration to ensure optimal performance and safety.Q: How do I use the modulating feature for industrial heating?

A: The modulating feature is controlled via automated systems or manually to adjust the gas flow and flame size. This allows precise temperature control tailored to specific industrial processes, optimizing fuel use and maintaining product quality.Q: What are the key benefits of using a stainless steel modulating gas burner?

A: Benefits include enhanced fuel efficiency, robust durability due to stainless steel construction, reduced operational costs, precise temperature regulation, and compliance with safety and environmental standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Nuway Gas Burners Category

Two Stage Gas Burners

Minimum Order Quantity : 1 Unit

Condition : New

Material : Mild Steel

Usage : Industrial

Color : Red & Black

Size : Sizes Available

Gas Burner

Minimum Order Quantity : 1 Unit

Condition : New

Material : Mild Steel

Usage : Industrial

Color : Red & Black

Size : Sizes Available

High Temperature Gas Burner

Minimum Order Quantity : 1 Unit

Condition : New

Material : Mild Steel

Usage : Industrial

Color : Red & Black

Size : Sizes Available

Gas Fired Infrared Burners

Minimum Order Quantity : 1 Unit

Condition : New

Material : Mild Steel

Usage : Industrial

Color : Red & Black

Size : Sizes Available

Send Inquiry

Send Inquiry