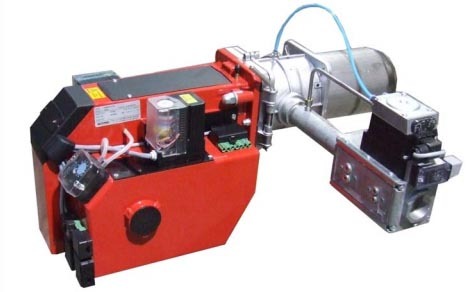

Two Stage Gas Burner

Two Stage Gas Burner Specification

- Condition

- New

- Usage

- Industrial

- Product Type

- Two Stage Gas Burner

- Color

- Red & Black

- Material

- Stainless Steel

Two Stage Gas Burner Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 4 Week

About Two Stage Gas Burner

Two Stage Gas Burner

Capacity - 300 to 1520kW

These burners are available for use on natural gas, LPG, towns gas and biogas with-

- single stage on/off

- two stage high/low

- or modulating operation.

They are typically suited for commercial hot water boiler systems and steam boiler systems.

Installation of a gas-fired heating system must be performed in accordance with the applicable regulations

and guidelines. It is, therefore, the duty of the installation engineer to ensure that all regulations have been

read carefully and understood. Installation, start-up and maintenance must be performed with utmost care.

The burner must not be operated in rooms with high levels of air humidity (laundry rooms), dust or corrosive

vapours. The boiler room must be ventilated accordingly with ventilation air.

Giersch MG20-DZM-LN Series gas burners are suitable for combustion of natural gas or liquid gas in

accordance with EN 437 and are in compliance with the EN 676 European standard.

Key Features:

- Quick and easy installation

- Reliable and trouble free operation

- Industry standard components available

- Most components can be easily accessed allowing for easy maintenance.

Also available:

- Larger gas train options

- Speed control (available only on certain models) to improve fuel efficiency and energy saving.

All M series burners have been design in accordance with EN676 and EN267.

Advanced Two Stage Operation

This gas burner incorporates a dual-stage mechanism, allowing for flexible adjustment of flame intensity to suit different industrial processes. By switching between low and high modes, users can achieve energy savings, reduce wear, and enhance operational safety. The two stage feature provides optimal control, making the unit highly adaptable to varying heating demands.

Premium Stainless Steel Design

Constructed from high-grade stainless steel, the burner is resistant to corrosion and wear, even in demanding industrial environments. This choice of material ensures long-lasting performance, minimal maintenance, and reliability, providing greater value to factories and processing units seeking consistent heat flow for their operations.

FAQs of Two Stage Gas Burner:

Q: How is the Two Stage Gas Burner used in industrial settings?

A: The burner is installed in industrial heating systems, where it alternates between two flame intensities to efficiently manage temperature requirements during production and processing activities.Q: What are the advantages of the two stage feature for gas burners?

A: The two stage system allows users to switch between high and low flame settings, resulting in better energy efficiency, reduced fuel consumption, and extended burner life. It also delivers more precise heat control for diverse industrial applications.Q: When should I choose a stainless steel two stage burner for my facility?

A: Opt for a stainless steel two stage burner when seeking greater durability, resistance to corrosion, and the need for adaptive heating in fast-paced or high-temperature industrial environments.Q: Where are these two stage gas burners distributed and supplied in India?

A: Our burners are available through a comprehensive network of distributors, exporters, importers, service providers, suppliers, and traders located throughout India, supporting various industrial regions.Q: What is the installation process for a new two stage gas burner?

A: Installation typically involves connecting the burner to the gas supply and integrating it with existing heating or processing equipment. It is recommended to seek professional service providers for safe and efficient setup.Q: How does the two stage operation benefit my industrial process?

A: The dual-stage capability enables operators to match the burners output to specific process requirements, reducing operational costs and improving production quality through controlled, consistent heating.Q: Can the burner be used in environments with high corrosion risk?

A: Yes, the stainless steel construction makes the burner suitable for locations prone to moisture and corrosive elements, ensuring reliable performance and minimal maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Nuway Gas Burners Category

Gas Furnace Burner

Minimum Order Quantity : 1 Unit

Size : Standard

Condition : New

Color : Black

Usage : Industrial, Others

Product Type : Gas Furnace Burner

Single Stage Gas Burner

Minimum Order Quantity : 1 Unit

Size : Sizes Available

Condition : New

Color : Red & Black

Usage : Industrial

Product Type : Single Stage Gas Burner

Gas Fired Infrared Burners

Minimum Order Quantity : 1 Unit

Size : Sizes Available

Condition : New

Color : Red & Black

Usage : Industrial

Product Type : Gas Fired Infrared Burners

Automatic Monoblock Gas Burner

Minimum Order Quantity : 1 Unit

Size : Sizes Available

Condition : New

Color : Black & Gray

Usage : Industrial

Product Type : Automatic Monoblock Gas Burner

Send Inquiry

Send Inquiry